Wish I would've done a Before and After with the Dragy.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Steps in the Right Direction - Build Thread for my two Lightnings

- Thread starter FMOS Racing

- Start date

Well that was a lot bigger chore than I remembered! I was delayed a couple of times by pushrod length, and since I was staying with the stock pedestal rockers with no adjustability, that was a critical dimension. A myriad of other little delays and "Oh, man, c'mon" moments... plus being over 15 years older than the last time I changed a cam with the motor in the truck, added up to two pretty solid weekends on this thing.

One lesson learned is that the Remflex gaskets can push the headers outboard enough that the collector flange will touch the frame on the passenger side. I tried to pull the motor slightly to the driver's side in the motor mounts, but that didn't seem to make any difference. I need to clearance the flange and the frame a little.

One lesson learned is that the Remflex gaskets can push the headers outboard enough that the collector flange will touch the frame on the passenger side. I tried to pull the motor slightly to the driver's side in the motor mounts, but that didn't seem to make any difference. I need to clearance the flange and the frame a little.

Last edited:

Observations -

- Amazing how much quieter a new roller setup is than a 30 year old flat tappet in terms of engine racket.

- Nice little hot rod bump to it at idle, annoying gas smell occasionally, even with cats and a solid A:F.

- Not sure how much is the change in injectors, and how much the cam, but I had to pull a lot of fuel down low (probably injectors) and add a lot in the upper revs (probably the cam).

- All of the OEM smog stuff was shot. AIR pump was freewheeling, thermactor tubing was packed full of carbon, and there was a colossal vacuum leak in the tubing to the fuel vapor canister that I missed the last time I had the intake off. Eliminating that vacuum leak required a few generous turns to the idle adjustment to get it to run.

Working on the details in the tuning, but overall drivability was great after a few miles with autotune and then a couple rounds of VE Analyze.

I tried to reuse the rubber VC gaskets, but no bueno, have a leak on the passenger side, so new gaskets this weekend. I want to tweak the distributor rotation a little, too. But, otherwise, she's back to driving.

- Amazing how much quieter a new roller setup is than a 30 year old flat tappet in terms of engine racket.

- Nice little hot rod bump to it at idle, annoying gas smell occasionally, even with cats and a solid A:F.

- Not sure how much is the change in injectors, and how much the cam, but I had to pull a lot of fuel down low (probably injectors) and add a lot in the upper revs (probably the cam).

- All of the OEM smog stuff was shot. AIR pump was freewheeling, thermactor tubing was packed full of carbon, and there was a colossal vacuum leak in the tubing to the fuel vapor canister that I missed the last time I had the intake off. Eliminating that vacuum leak required a few generous turns to the idle adjustment to get it to run.

Working on the details in the tuning, but overall drivability was great after a few miles with autotune and then a couple rounds of VE Analyze.

I tried to reuse the rubber VC gaskets, but no bueno, have a leak on the passenger side, so new gaskets this weekend. I want to tweak the distributor rotation a little, too. But, otherwise, she's back to driving.

You have really brought that truck back to life. Awesome work.

Now that you’ve been all up in its business you know the engine better. Worth it!Observations -

- Amazing how much quieter a new roller setup is than a 30 year old flat tappet in terms of engine racket.

- Nice little hot rod bump to it at idle, annoying gas smell occasionally, even with cats and a solid A:F.

- Not sure how much is the change in injectors, and how much the cam, but I had to pull a lot of fuel down low (probably injectors) and add a lot in the upper revs (probably the cam).

- All of the OEM smog stuff was shot. AIR pump was freewheeling, thermactor tubing was packed full of carbon, and there was a colossal vacuum leak in the tubing to the fuel vapor canister that I missed the last time I had the intake off. Eliminating that vacuum leak required a few generous turns to the idle adjustment to get it to run.

Working on the details in the tuning, but overall drivability was great after a few miles with autotune and then a couple rounds of VE Analyze.

I tried to reuse the rubber VC gaskets, but no bueno, have a leak on the passenger side, so new gaskets this weekend. I want to tweak the distributor rotation a little, too. But, otherwise, she's back to driving.

I'd gone through it back when I bought it because it was smoking so badly, but at that point I was just trying to get it drivable and capable of passing a safety/smog inspection. This time I had a different agenda.

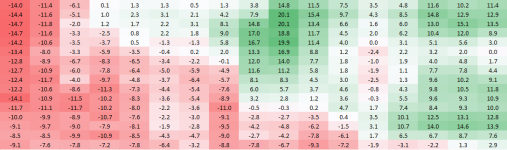

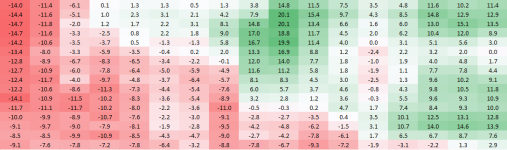

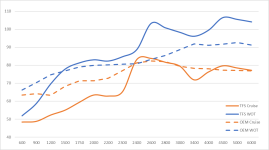

Thought this might be interesting. In the table below, the rows are load from 20 to 100, and the columns are RPM from 600 to 6000 at irregular intervals. I left the scales off since I had to do a little manipulation because I rescaled both load and RPM axis a bit.

This is the change in VE from new tune to old. I had to reduce the lower RPM range fuel requirements and raise the upper RPMs by the amounts shown (VE percentage). One fascinating change is how dramatically the height of the ridge at 2400 RPMs increased. I'm GUESSING that the cam lines up really well with the ram tuning effect of the manifold at that point. It seems that stock cam peaks in the 3600-3800 RPM range, which the small difference in VE that rev range indicates, and then the TFS-1 requires a lot more fuel at the higher RPMs because it's still pulling hard.

I'm still tweaking in the tune, but it's close. Also, I'd never noticed before that MAP load never gets to 100 at WOT. I'm so used to dealing with boosted vehicles, I didn't realize that naturally aspirated never got to baro. I wonder if a bigger throttle body would get that last 2-4 kPa?

This is the change in VE from new tune to old. I had to reduce the lower RPM range fuel requirements and raise the upper RPMs by the amounts shown (VE percentage). One fascinating change is how dramatically the height of the ridge at 2400 RPMs increased. I'm GUESSING that the cam lines up really well with the ram tuning effect of the manifold at that point. It seems that stock cam peaks in the 3600-3800 RPM range, which the small difference in VE that rev range indicates, and then the TFS-1 requires a lot more fuel at the higher RPMs because it's still pulling hard.

I'm still tweaking in the tune, but it's close. Also, I'd never noticed before that MAP load never gets to 100 at WOT. I'm so used to dealing with boosted vehicles, I didn't realize that naturally aspirated never got to baro. I wonder if a bigger throttle body would get that last 2-4 kPa?

That high VE ridge exists with the stock cam, but it's extreme with the TFS. I thought for a while that it was because of the way I was tuning it to run lean on the highway, but then realized that was backwards, if it incorporated leanness into the VE, the ridge would be lower, not higher. I divided the RPM scale in that range into a few segments to try to get some granularity to how fast the VE increases, and it's abrupt. Pretty wild.

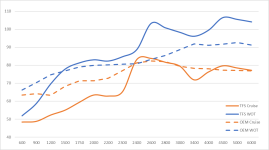

Cross sections of TFS and OEM VE at 60 kPa (Cruise) and 95 kPa (WOT). Note the RPM scale between 2000 and 3000 rpms. That increase is steep!

Cross sections of TFS and OEM VE at 60 kPa (Cruise) and 95 kPa (WOT). Note the RPM scale between 2000 and 3000 rpms. That increase is steep!

Last edited:

Jamie V

Well-known member

I'd never noticed before that MAP load never gets to 100 at WOT. I'm so used to dealing with boosted vehicles, I didn't realize that naturally aspirated never got to baro. I wonder if a bigger throttle body would get that last 2-4 kPa?

View attachment 104147

Some engines can never get to 100 KPA, and some engines can go well over 100 KPA. I’m not sure if it’s an efficiency of the engine type thing or what.

They can have VE greater than 100% thanks to valve timing and intake synergy (note that the one above is in several places), but MAP can't be higher than barometric pressure (about 101.5 kPa for me here in Raleigh) without boost.

Last edited:

Some engines can never get to 100 KPA, and some engines can go well over 100 KPA. I’m not sure if it’s an efficiency of the engine type thing or what.

Anything is possible if you do it wrong enough. Like Nitrous backfire is what I was thinking.They can have VE greater than 100% thanks to valve timing and intake synergy (note that the one above is in several places), but MAP can't be higher than barometric pressure (about 101.5 kPa for me here in Raleigh) without boost.

Aaannnndddd.... I forgot to change the distributor gear. Thankfully, I decided to clock the distributor a little differently while I was changing the valve cover gaskets, and noticed that, in the 430 miles I'd driven it, the gear teeth were about 50% gone. I'm pretty relieved that I didn't procrastinate with the gasket change, or I would've been sitting on the side of the road somewhere wondering what in the world was going on.

It would lay down really hard at upper revs and occasionally miss, and I couldn't figure out why.

I stuck the distributor from the red truck in it until I can get a proper replacement.

It would lay down really hard at upper revs and occasionally miss, and I couldn't figure out why.

I stuck the distributor from the red truck in it until I can get a proper replacement.

Last edited:

Aaannnndddd.... I forgot to change the distributor gear. Thankfully, I decided to clock the distributor a little differently while I was changing the valve cover gaskets, and noticed that, in the 430 miles I'd driven it, the gear teeth were about 50% gone. I'm pretty relieved that I didn't procrastinate with the gasket change, or I would've been sitting on the side of the road somewhere wondering what in the world was going on.

It would lay down really hard at upper revs and occasionally miss, and I couldn't figure out why.

I stuck the distributor from the red truck in it until I can get a proper replacement.

oh the simple things to overlook sometimes. what material are you going to go for. Im not sure i can get on board with a composite one for something that i expect to have longevity. I went with steel.

Steel. I've held a composite gear in my hand, and I'd need someone that had ran one for a long time to tell me it's awesome before I'd want to put one in the motor.

Last edited:

A couple of things related to tuning that are noteworthy. Dialing this thing in to the level it was with 19# injectors and the stock valve train doesn't seem possible. I'm having to lean on O2 correction more than I did before, so I've turned up the PID response and given it a bit more range than previously. The correction can swing plus to minus for the same load/rpm range with the change in daytime temperature, even with similar MAT temperatures.

I've also raised my 30+ percent throttle shift points, both up and down, pretty significantly to make up for somewhat less of a midrange - it's more apt to lug a little bit in OD at low speed and light throttle on an incline, so I've set it up to downshift more enthusiastically.

Pluses are way better behavior when it does downshift all the way through WOT to the upshift. It's a nice upgrade.

Batch fire, 60# injectors, and a more cam.

I've also raised my 30+ percent throttle shift points, both up and down, pretty significantly to make up for somewhat less of a midrange - it's more apt to lug a little bit in OD at low speed and light throttle on an incline, so I've set it up to downshift more enthusiastically.

Pluses are way better behavior when it does downshift all the way through WOT to the upshift. It's a nice upgrade.

Batch fire, 60# injectors, and a more cam.

Regarding Calculated fuel, Did you do the “Double injector size” with the 60’s or go exact? I’ve been wondering if and why it matters.A couple of things related to tuning that are noteworthy. Dialing this thing in to the level it was with 19# injectors and the stock valve train doesn't seem possible. I'm having to lean on O2 correction more than I did before, so I've turned up the PID response and given it a bit more range than previously. The correction can swing plus to minus for the same load/rpm range with the change in daytime temperature, even with similar MAT temperatures.

I've also raised my 30+ percent throttle shift points, both up and down, pretty significantly to make up for somewhat less of a midrange - it's more apt to lug a little bit in OD at low speed and light throttle on an incline, so I've set it up to downshift more enthusiastically.

Pluses are way better behavior when it does downshift all the way through WOT to the upshift. It's a nice upgrade.

Batch fire, 60# injectors, and a more cam.